MIL-DTL-1222J

Conformance inspection and tests.

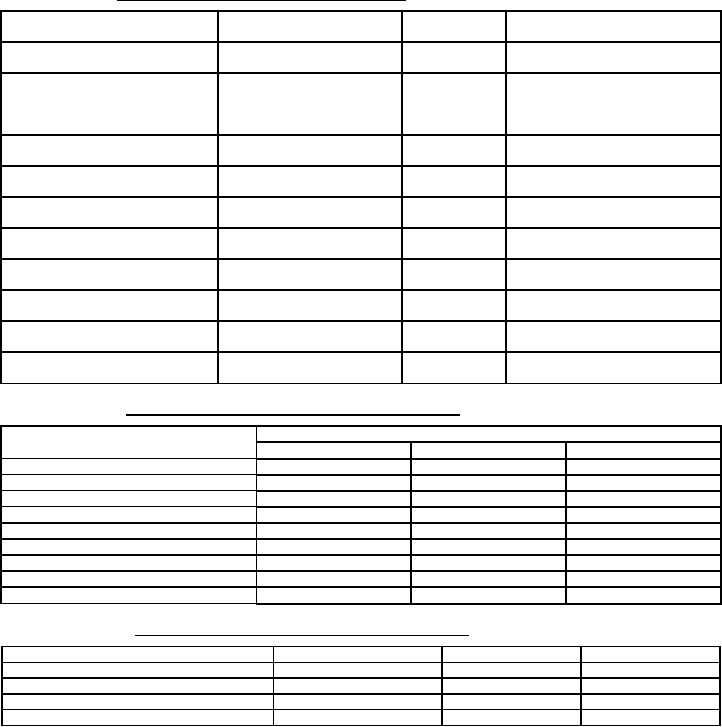

TABLE XI.

Requirement

Test

Inspection/Tests

Sampling Requirements

Paragraph

Paragraph

1.2.1, 3.6, 3.10,

Visual

4.3.1

Plan A in table XII

3.13 & 3.15

Titanium:

100 per cent

Inspection for defects

3.15

4.3.2

All other alloys:

Plan B in table XII

Dimensional

3.9

4.4

Plan A in table XII

Dimensional after

3.9

4.4

Plan A in table XII

coating

Magnetic permeability

3.8

4.5.4

Plan A in table XII

Coating thickness

3.6.3

4.5.5

Plan C in table XII

Chemical analysis

3.1

4.5.1

One test

Mechanical properties

3.4

4.5.2

Plan C in table XII

Hydrogen embrittlement

3.7

4.5.6

Plan C in table XII

Decarburization

3.5

4.5.3

One test

TABLE XII.

Sample size for inspections and tests.

Sample Size

Lot size

Sampling Plan A

Sampling Plan B

Sampling Plan C

2

to

3

All

All

1

4

to

15

3

3

2

16

to

90

5

5

2

91

to

150

8

8

3

151

to

500

9

13

3

501

to

1,200

9

20

5

1,201

to

10,000

9

32

5

10,001

to

35,000

10

50

5

35,001

to

250,000

10

80

8

TABLE XIII.

Mechanical Property Test Requirements.

Test

Bolts and Screws

Studs

Nuts

Hardness

Required

Required

Required

Proof stress or yield stress

Required

Required

Required

Axial tensile strength

Required

Wedge tensile

Required

42

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business