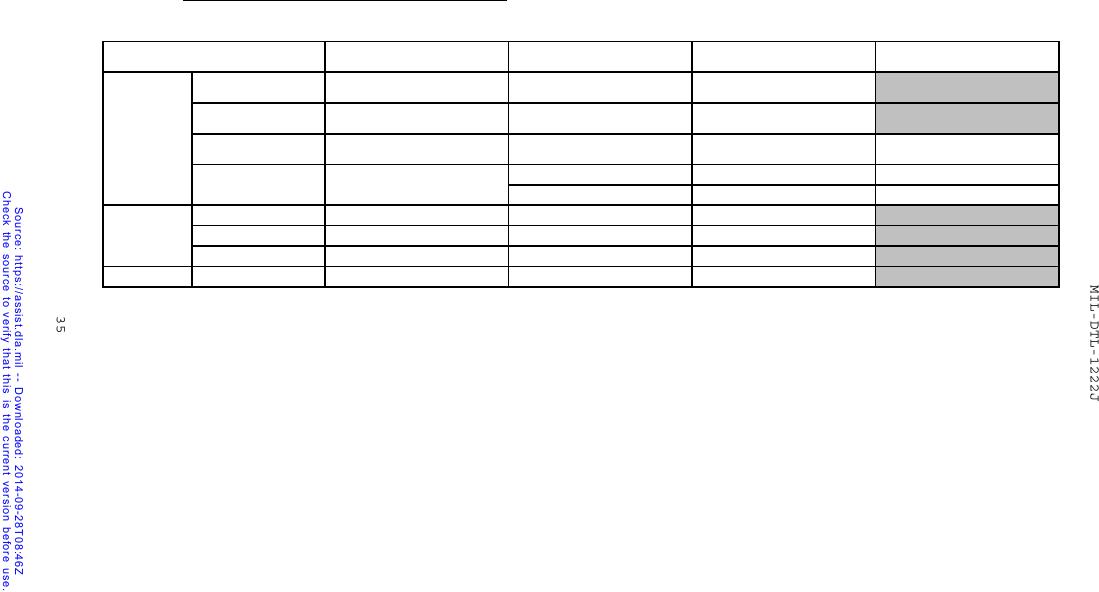

TABLE IV.

Mechanical property values for nuts. - Continued

Heat treatment or

Nominal size

Proof stress for 1

condition

(inches)

hex nut (ksi min)

Rockwell hardness

Material

As formed or stress

400

All sizes

80

relieved

As formed or stress

6

405

All sizes

80

relieved

Nickel

Annealed and age

500

All sizes

130

C24 min

hardened

9

9

2¼ or less

120

B85-C35

9

Annealed

625

9

9

B85-C35

Over 2¼

110

2024

T4

All sizes

55

Aluminum

6061

T6

All sizes

40

7075

T73

All sizes

52

8

Titanium

T7

Annealed

All sizes

120

Notes:

1 To determine minimum proof stress for nuts other than hex nuts use the following:

(a) Proof stress for jam nuts (all materials) = 0.60F.

(b) Proof stress for heavy hex nuts (ferrous) = 1.10F.

(c) Proof stress for heavy hex nuts (nonferrous) = 1.08F.

(d) Proof stress for slotted nuts (all materials) = 0.80F.

(where F = proof stress for hex nut.)

2 There is no minimum in the commercial specification.

3 HRB 97 was used instead of HRC 19 because the Rockwell C hardness range does not cover HRC 19.

4 The commercial specification has a higher minimum.

5 The commercial specification has a higher maximum.

6 The commercial specification has a lower minimum.

7 The commercial specification has a lower maximum.

8 The commercial specification has a higher minimum.

9 There is no commercial fastener specification for this fastener

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business